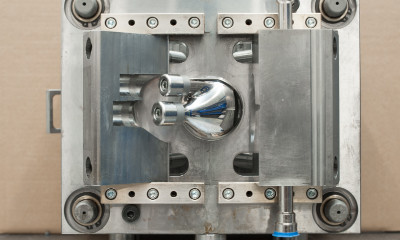

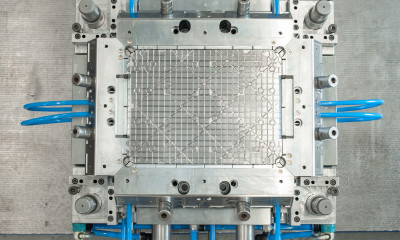

We offer product development from design to the finished product. It includes the design and manufacture of injection mould, optimisation of the workpiece and the mould for performance and production of plastic workpieces.

Being experienced representatives of the plastics processing industry equipment manufacturers, we cooperate with our customers at every stage of their particular solution implementation, offering expert knowledge. We conduct an audit and detailed feasibility study. As well as simulations of the injection process, manage the implementation of complete production lines, and their further development, and integration with industrial automation.

We work closely with medical, pharmaceutical, and automotive industries.

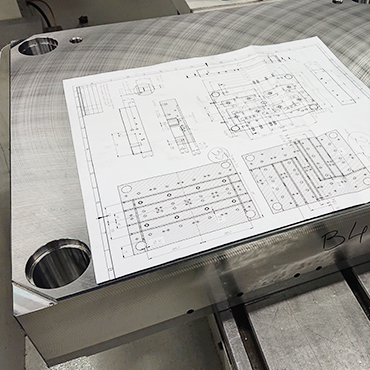

We have software – NX 10 for designing injection moulds and for CAM.

01 Machine park

CNC 3-axis machining centre

DMC 1,150 V

X/Y/Z 1150/700/550

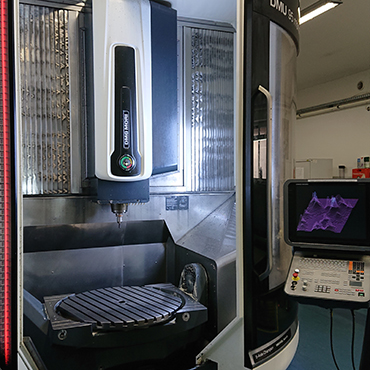

CNC 5-axis machining centre

OPS Ingersoll SPEED HAWK 650

With machinable graphite electrodes

X/Y/Z 650/550/450

CNC 5-axis machining centre

OPS Ingesoll SPEED HAWK 550

With option of titanium processing

X/Y/Z 550/400/400

CNC 5-axis machining centre

DMU95 MonoBLOCK

X/Y/Z 950/850/650

Surface grinder

ORSHA OSH400

X/Y/Z 1100/450/400IXION IA 1TL

Drilling machine

SODICK K1C

X/Y/Z 200/300/250

Zakres średnic fi 0,4-3,0

EDM die-sinking machine

OPS Ingersoll GANTRY EAGLE 500

X/Y/Z 520/350/280

Wire cutting machine WEDM

SODICK SL 600G

X/Y/Z 600/400/300

CNC lathe

SPINNER PD-CNC

Dmax fi 40

CNC 3-axis machining centre

AVIA VMC 1300

X/Y/Z 1300/700/670

CNC 3-axis machining centre

AVIA VMC 800

X/Y/Z 800/540/620

CNC deep-hole drilling machine

IXION IA 1TL

Dmax/Lmax fi16/600

Dry ice cleaning machine

Cold Jet i3 MicroClean

Our team consists of experienced designers, we also regularly cooperate with external specialists

in the field of mould design.

We have a fully equipped and self-sufficient tool room, where modern numerically controlled machines are used, including three 5-axis milling centres. We use Haidenhain, Andron, Fanuc software and 3D measuring machine.

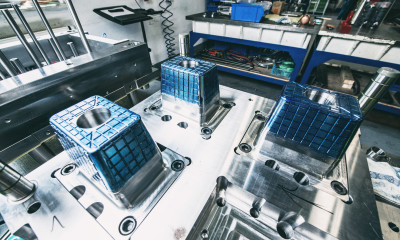

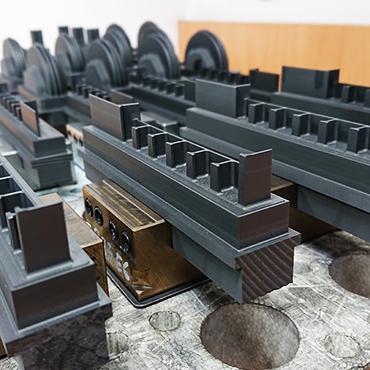

We specialize in moulds for the medical and automotive industries, and for manufacturing hot runner systems and hot halves.

Precisely planned work enables strict quality control at every stage of machining (detailed progress reporting).

Our sample projects

02 Tool services

We provide service machining, special instruments, and graphite electrodes.

Quick-clamping tops for CNC machining – Jigs

Electrodes – 3 and 5 axis HSM machining of graphite electrodes for EDM in EROWA system

Deep hole drilling – Lmax=600 Dmax=16

03 Quality control

Quality control takes place at every stage of production, from the acceptance of the first good piece to the release of workpieces for shipment.

ISO 9001 and IATF 16949

Production according to GMP

Zeiss Contura 3D measuring machine

To schedule a consultation with our representative, please contact us.

Tool making and injection moulding

Norbert Kowalkowski

+48 725 545 005

norbert.kowalkowski@wadim.com.pl

Assistant Project Manager

Beata Anczarska

+48 725 404 014

beata.anczarska@wadim.com.pl